Reducing costs with a Heavy Duty High Flow Vacuum Sealer

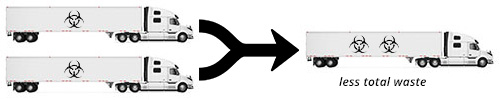

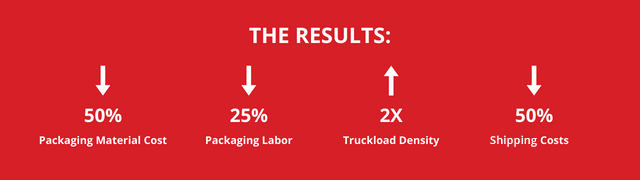

Heavy Duty, High Flow (HDHF) Vacuum Sealer Reduces Truck Shipments by 50% (Summer 2022)

THE NEED: One of the largest clean power generators in North America was searching for a complete packaging solutions provider to develop improved materials, machines, and vacuum sealing methods for packaging low-level hazardous materials for disposal. Their current methods were costly due to a slow manual process (that did not include vacuum sealing) and excessive hazmat-placarded truckloads due to bulky materials. This resulted in excessive:

- Shipping costs

- Material usage

- Labor costs

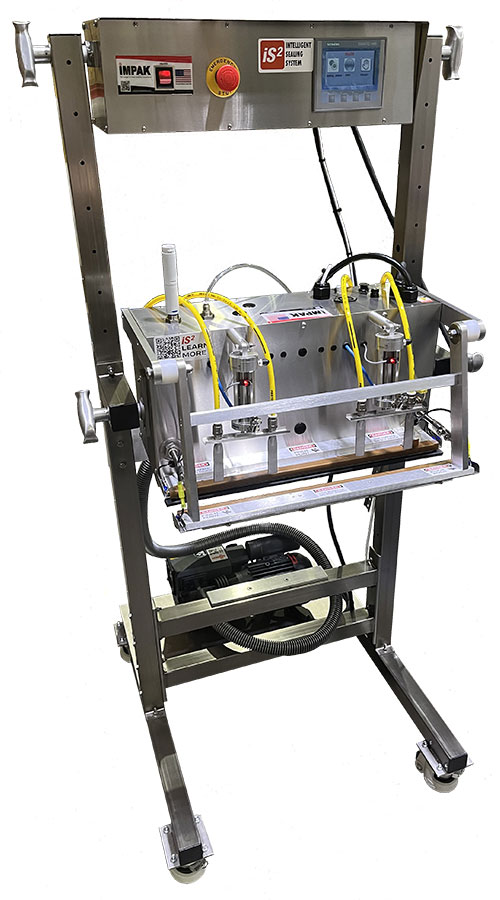

THE SOLUTION: IMPAK and Sorbent Systems met the challenge to increase the velocity of the packaging process and maximize / optimize density of truckload shipments. IMPAK suggested their industry-leading Gramatech Custom Pak Hi-Production Vacuum Packaging System, with iS2 Intelligent Sealing System - Temperature Control Heat, auxiliary vacuum motor and recommended Trident Nozzle System additional set of vacuum nozzles. Other customized solutions are available.

Normally the Gramatech Custom Pak Vacuum Sealer uses a Venturi pump to create 5 to 6 CFM of vacuum, with a high flow option of up to 10 CFM. Since a faster vacuuming process was desired, our engineering staff developed systems to provide faster air evacuation from an auxiliary vacuum pump - using an external Busch pump that delivers a flow rate of 40 m3/hr (23.5 CFM). This pump requires 220V power to run, however, and the customer only had 110V power available in the space where the sealer would be used.

The two options we presented were:

- To step down the vacuum capabilities of the pump to 21 m3/hr (12.4 CFM), the maximum possible with 110V

- To add a VFD and transformer to the machine in order to take advantage of the full 40 m3/hr vacuum available to the Busch pump while using just a 110V power supply

The customer chose the former option in order to save time and expense, while still getting a machine that would deliver a strong vacuum seal fast enough to make a huge improvement in their ability to quickly process high volumes of hazardous materials.

Truck shipments reduced by 50%

The final version of the customized sealer incorporated the following specifications:

- Seal Length: 41” (1042 mm)

- Seal Width: ½” (12.7 mm) - standard width is 1/4" (6.35 mm)

- Recommended optional 20 m3/h (cubic meters per hour) electric vacuum pump

- Trident 4 Nozzle Configuration – a recommended option that includes two additional stainless steel nozzles for faster air evacuation

- Temperature Control System – IMPAK’s proprietary, Siemens-based Intelligent Sealing System (iS2)

- Adjustable seal head angle for horizontal or vertical use

- Pneumatically controlled low-pressure jaw close safety system with release if obstruction is detected

- Foot pedal cycle activation

- Air requirement (min): 100 psi

- Electrical requirement: 115V

- Made in USA

These images show the Heavy Duty, High Flow (HDHF) Vacuum Sealer before final housing is added:

See this sealer in action: